Mark Isaacs has a vision: He believes buildings can be more energy-efficient without costing more and that his approach can create living-wage jobs for disadvantaged people. To get there, though, he’ll need to convince architects and builders to make some fundamental changes.

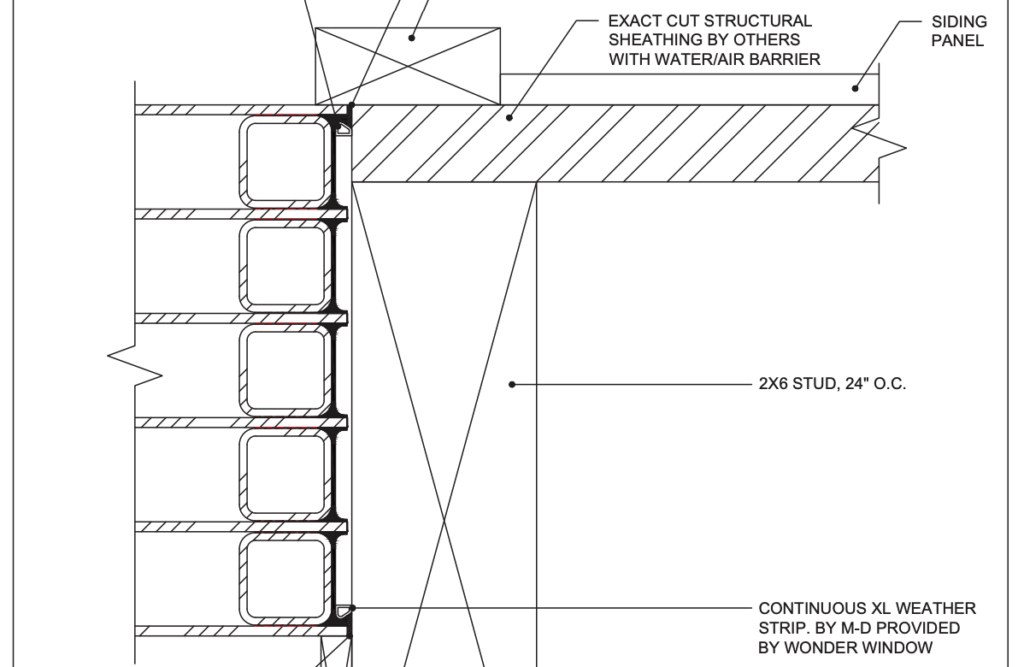

His vision starts first with WonderWindows, multi-pane acrylic fixed windows that are 2 to 4 times more energy-efficient than today’s windows in maintaining interior comfort. Second, he advocates for changes in how builders frame the walls in a house or building, moving to 24-inch on-center framing, which decreases heat transmission around his window. Third, he wants to change how we manufacture windows: Isaacs’ goal is to empower individual craftspeople to build his windows closer to job sites. That would create living-wage jobs for moderate-skill laborers and cut down on the environmental inefficiencies of long-haul transport.

“I’m basically an advocate for 24-inch-on-center framing. It ultimately saves money compared to two-by-four, 16-inch-on-center that most of us see,” he said. He notes that he needs to create “one convert at a time” to this method, but when they see success, they’ll evangelize the concept so that it becomes more and more accepted in the industry.

His ambitions are lofty, but Isaacs moved closer to his goal in all three areas in 2022. For one, he’s completed the process of getting his windows tested to national standards and International Codes Council review for quality and code compliance.

In Spring 2022, Isaacs pitched his way into the inaugural CoBuilders cohort. He says the accelerator and a subsequent Mississippi Seed Fund award enabled him to launch his first “Makers Workshop.” Working with the Boys and Girls Club of the Gulf Coast, in Bay St Louis, he’s able to teach teens and junior staff adults —how to manufacture his windows. The program gives the makers hands-on experience with a craft while Isaacs can test the manufacturing process and deliver sample windows to architects and builders to share with their clients and colleagues.

“An architect or builder can’t convince his client that this is the right thing to do without showing them the view. I’m very pleased with the leaps and bounds that we’ve made,” he said. “We’re making some very high-quality windows at this point.”

The year culminated for Isaacs in December when he taught a continuing education course on his approach to building Net-Zero Energy buildings to the American Institute of Architects chapter in New Orleans. The following day, he flew to Clearwater, Florida, where he was invited to present his first peer-reviewed technical paper to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) “Buildings XV” Conference. ASHRAE convenes the meeting every three years to look into new technologies and techniques for advanced building energy efficiency and comfort. He said it was gratifying to be received by the professional organization of building scientists and engineers.

“The Buildings Conference gave me an opportunity to meet leading building scientists at Oak Ridge and Berkeley Labs, some for the first time face-to-face, and today they are colleagues in research soon to get underway.”

The US Department of Energy has made a Cooperative R&D award to Oak Ridge National Labs to model the affordable cost of net-zero energy performance for hotels, multi-family townhouses and flats, and office buildings using Isaacs’ windows and 24-inch on-center framing. The Department of Energy V-QUAD Regional Accelerator of the Mississippi Development Authority granted $20,000 to the Mississippi State University College of Architecture for CAD-based modeling of Isaacs’ windows and 24-inch on-center walls to dovetail with the Oak Ridge National Labs energy and cost modeling work. The goal is to show how it saves money on “first cost” as well as in the long run.

Isaacs says today’s cutting-edge “high-efficiency” windows use double-paned glass with argon gas and low emissivity coatings to reach thermal resistance, or R-values, of 3.3 to 3.8 at the top end. Unfortunately, this R-value degrades to R2 when placed in aluminum frames, as we see in most commercial buildings. His windows, combined with the different framing techniques, get to “R6 through R9… two to four times the typical energy efficiency of current windows.”

If he can convince professional builders and architects to try the windows, show that the framing process is cheaper even at the outset, and demonstrate that the manufacturing process can have a positive social impact—he thinks he’ll have a winner.

“This is the way building technology works. It’s way slower than consumer electronics in embracing change,” Isaacs said. But he points out that there have been significant changes in buildings over the past decades, while, at the same time, other technical advances in highly-efficient windows haven’t panned out as promised.

“That continues to make an opening for us—so to speak,” he said.